Peplink Steers Construction Vehicles Towards an Autonomous Future

In a pilot project, Peplink provided construction company Steer the connectivity necessary to remotely operate semi-autonomous construction equipment. With the help of SpeedFusion technologies, they could remotely drive vehicles to collect and dump dangerous construction debris. By doing so, Steer were able to increase productivity, reduce costs and ensure the health and safety of their employees.

Challenge

Steer, a Norwegian startup that provides autonomous solutions for construction equipment, required products and technology that could deliver unbreakable connectivity. They needed Peplink to power their network of semi-autonomous construction vehicles in a rural site located 300km away from their datacenter.

As 4G coverage was known to be unstable in the area, a sustained connection to remotely manage these vehicles was important. This connection was required to operate large Caterpillar 730s and mini Caterpillar dump trucks, all fitted with a semi-autonomous remote control system. Peplinks SpeedFusion technology overcame this challenge with its Bandwith Bonding and Hot Failover technology, integrated within the powerful CPUs of the products.

The aim was to remotely drive these dump trucks for approximately 7km, carrying over 30,000 cubic meters of construction debris. Then, once arrived at the desired location, an operator would take over and dump the load.

Solution

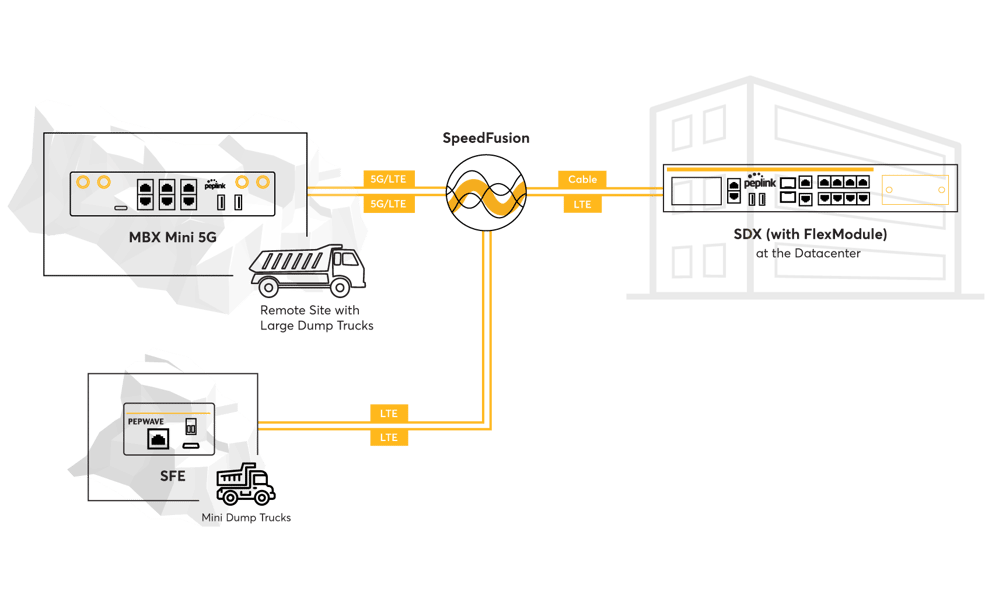

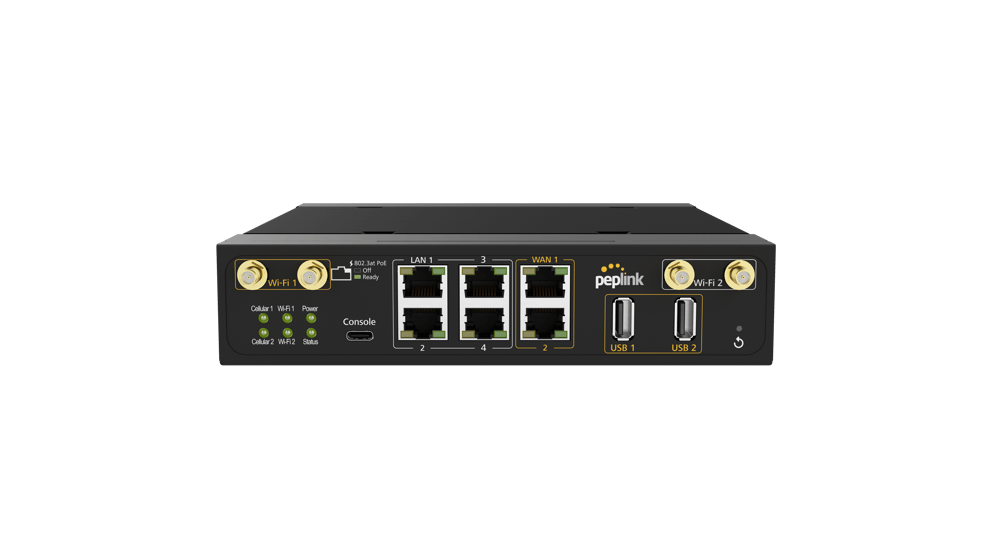

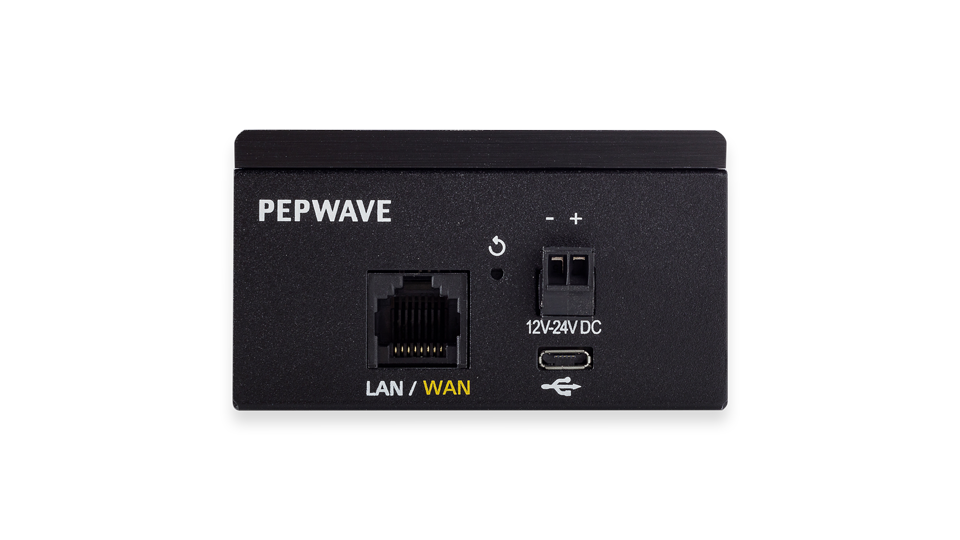

The network can be split into three segments: the remote site, the center and the network of mini Caterpillar trucks. For the remote site, initially the MBX HD2 was used for their network. However, all the WAN ports weren’t needed, so Steer opted for the MBX Mini instead. For their center, the SDX, with an additional FlexModule, was deployed. For mini Caterpillar trucks, SpeedFusion Engine was installed.

The MBX Mini utilized SpeedFusion’s Bandwidth Bonding and Hot Failover technology to achieve powerful speeds and system redundency, two critical criteras for remote management of autonomous vehicles. It’s embedded 5G modems and throughput made it perfect for powering the large Caterpillar 730s.

The SDX acts as another end-point to enable the use of SpeedFusion technology. With it’s 12Gbps thoughput, this powerful device had the ability to handle the network requirements for the entire system. It was fitted with a cellular expansion module to provide a backup LTE source. The connection offered reliability through its Ethernet cables and backup LTE source.

SpeedFusion Engine was used to control the mini Caterpillar trucks. This device’s small form factor made it suitable for the trucks. It’s economical scalability ensured its adaptably and flexibility for any type of network. It’s plug-and-play integration made installation quick and easy.

Result

The outcome of this project was very successful. Over a period of 3 months the increased productivity outperformed what any human operator could achieve. As the vehicles could be remotely accessed 24/7, employees were able to cut travel time to the site as well as operate the vehicles at any time of the day.

Most importantly, employee health and safety was prioritized, as these types of sites are known to be hazardous working environments. This is due to the unpredictable terrain and dangerous materials such as explosives, radioactive materials, avalanches, landslides, etc.